Reading time: 26 minutes

A conversation with the Developer and elysia Owner Ruben Tilgner

By Fritz Fey, Photos: Fritz Fey

(Courtesy of Studio Magazin Germany, translated by elysia)

There are a striking number of passionate people in our industry, both on the manufacturer and user side, who talk about their work with glowing eyes. In the vast majority of cases, I look for my interlocutors on the user side, but it’s not always so easy to tell user and developer apart, because there are also contemporaries who – for good reason – are on both sides. One of these audio enthusiasts, who enjoy the privilege of being able to build the equipment they would like to use themselves, is called Ruben Tilgner and is the owner of the German analog equipment specialist elysia, which has been operating since 2006 with the clearly defined goal of giving analog technology an innovative, forward-looking face. Discretely constructed Class A technology forms the basis for the kind of sound quality that Ruben Tilgner wants as a user, without overlooking the fact that the contemporary studio is dominated by the DAW, i.e. digital technology.

After a longer Corona break, I took the opportunity to visit Ruben in his high-tech wizard’s kitchen. With an unmistakable gleam in his eyes, he shows me the production department, which has been optimized for self-sufficiency and now also benefits from automated SMD assembly and metal processing. But actually, we want to spend the day as usual with 19-inch erotica and nerd talk, for which we go to a very special room that can alternatively be used as a creativity-giving recording room, meeting room or cozy lounge due to its careful acoustic design. A few doors down, there is a sound control room equipped with a conspicuous amount of elysia equipment, just as if there were a source in the immediate vicinity.

Little Ruben, who was interested in lighting effects from a young age and wanted to know exactly where the sounds coming from his toy car were coming from, now belongs to an endangered species of experts who are considered the guardians of analog technology and who use their brains and hearts to ensure that valuable know-how in the service of good sound is not lost. Like most of my interviews, this one starts with the question of how it all began… in this case with a toy car disassembled into its component parts!

Ruben Tilgner: I’ve always been curious to find out how technical things work. When I was a little boy, I got a toy car for Christmas and I wanted to find out where the noises it made came from. A week later, it didn’t drive anymore because I had taken it apart into its component parts. I was maybe six years old then. A few years later, my first contact with electronics came through my cousin, who was training to be a radio and television technician. My father was very supportive and recognized my enthusiasm. At the age of ten, I started taking piano lessons, so you can almost imagine how music and technology connected in my mind. Oddly enough, at first, I was more focused on light, on everything that flashed and glowed.

The light organs and disco balls in party basements motivated me to experiment with light effects in my childhood room, for example with a rotating bicycle lamp on my record player. Apparently, I was quite talented and very quickly had a small workshop in the basement for tinkering and soldering. You have to remember that there was no YouTube at that time, but I had three or four books and just tried wildly. At sixteen, I started an apprenticeship as a radio and television technician, practically my entry into the ‘real’ world of electronics.

On the very first or second day of my apprenticeship, I came home and my father said that the TV stopped working. I found out that some diodes in the power supply were broken, got the spare parts from my supervisor, and the TV worked again. From a technical point of view, I didn’t get much out of that time, because the company where I was trained wasn’t a big one, but in retrospect, due to my personal initiative, it was the perfect foundation for analog circuitry, because all devices in consumer electronics were still discrete. If you unscrewed an amplifier back then, you wouldn’t find any ICs, but everything was built with transistors and resistors.

I still have a book from that time, which I like to look at because it’s amazing how cool the circuitry was back then that the developers had. I have a lot of respect for the engineers who developed color TVs and VCRs back then. They were real cracks. At the same time, I started playing in bands with the piano and electric bass, for a few years as a bass player with self-composed songs, and later as a keyboard player. The first thing we had, however, was of course a lighting system with a corresponding mixer, all built by ourselves.

Actually, we had more light than sound (laughs). During the apprenticeship, I already realized that this pure repairing would become boring in the long run, because at some point everything was based on routine and experience – always the same mistakes that you knew practically in your sleep. After the apprenticeship came civilian service and a vocational baccalaureate. During my high school graduation, a buddy of mine told me that he knew of a company where you could work while you were at school. The company was called SPL and was located nearby. So I started to work there in the production – assembling boards, soldering, testing. At some point, I was asked if I wanted to be part of the team. It was a great time, a young team, but also successful products in exactly the field I wanted to work in, without actually knowing it at the beginning. Together with a friend, we came up with the idea for a kind of ‚Exciter’, which we called ‘Freshman’.

But the topic was settled for the time being, because SPL hired me permanently. I quickly learned the ropes and began to understand the essence of dynamics processing, something I had never had any contact with before. I also saw how devices were built and how to make the whole thing production-efficient. By reworking existing products, I then came up with completely independent developments, such as the Dynamaxx, which was launched in 1997. The brief was to design a compressor that was as simple as possible. The thing already worked great, even with complex signals, and was used a lot in the live area. It was a lot of fun to work on the details of such a circuit and to experience how the components ‘communicate’ with each other. Anyway, I noticed that my musical vein suddenly became very important, designing the control processes with this in mind.

Fritz Fey: You stayed with SPL as a developer for a long time before I heard about your plans to start your own business. Did you need this freedom for your personal development?

Ruben Tilgner: After ten years, I naturally had my own head and it was no longer so easy for me to develop ‘on assignment’. My later partner Dominik Klaßen originally wanted me to build a bass preamp for him. That’s how we got to know each other. The preamp was never built, but I started to realize more and more of my own ideas in circuits, which later formed the basis for the vision of the first elysia product, the alpha compressor.

Fritz Fey: Earlier we talked about simplifying dynamics processing. The alpha became the complete opposite of that, with what felt like eighty parameters (grins)…

Ruben Tilgner: The alpha was intended to be a high-quality mastering toolbox, but the basic quality of the stages was created when collecting ideas for Dominik’s bass preamp. That was such an increase in quality that it practically called out to become the basis for a complex circuit design. This drove my innovative spirit on how to make a device that would work differently or better in sum than a normal compressor. The first sketch I made for it ended up being almost 1:1 the alpha compressor. I took the prototype to various studios to collect reactions because I wasn’t a mastering engineer. Rather, I was looking at it more from the technical side, but I also wanted to create something new without having been asked for it by users.

Dissatisfaction is a good driving force for innovation. In mastering, ‘recording’ compressors were actually used, which often became audible at one dB. There had to be more to it than that. At that time, I was also regularly on the road as a live mixing engineer, and I didn’t really like the analog compressors that were being used. Vocals demand a lot of punch from a compressor because the forces at work at a concert like that have to be tamed somehow.

When I took my alpha prototype with me, I noticed how absolutely upfront the vocals were, without any control action or even signal degradation being heard. A compressor like this should be able to make a 10 dB boost without you noticing much of it. In the end, this also suited mastering, even if you certainly don’t control 10 dB there. If you look at two cars driving 100, it’s a different feeling to sit in the S-Class than in a small car. Actually, the alpha defined the entire sound philosophy of the company.

Fritz Fey: The alpha was also a real statement for me at the time: ‘This is what we can do’. In principle, all subsequent products were derived from this template, which, by the way, also became more affordable (grins).

Ruben Tilgner: When you see the mechanical effort that went into this device, which is still a lot of work in manufacturing today, you know that we wanted to set an example in every respect. At the time of its creation, it was common in mastering, for example, to overdrive the A/D converters to be really loud. My idea was to solve this in a more elegant and controllable way, by installing a ‚Soft Clipper’.

Actually, I could hardly be stopped by my will to innovate. I don’t know whether a mastering engineer would have come to me with this idea. I simply wanted to offer a lot. The continued interest in this device shows to this day that it was a good idea to put so much thought into a product and to push the quality to the extreme. I don’t think the user can define such quality. But I need a musical and technical understanding to recognize such a need. I had a vision myself of how such a device should sound – bigger, more open, more spectacular, more emotional. This vision drives me to this day to find the direction, even if the solution sometimes lies not in a magical high-tech component, but quite profanely in the design of the power supply.

Fritz Fey: It’s been a long road, from a boy spinning a bicycle lamp on a turntable to a developer designing mastering-grade equipment….

Ruben Tilgner: That’s right (smiles). In my last years at SPL, I started to get involved with discrete circuitry. The first products I developed there were rather classically built with op-amps. After that, the next step simply had to come, which I saw in discrete circuit design. I taught myself most of what was necessary for that. For example, the SPL gain station uses a discrete operational amplifier that I developed. But before that, there were many experiments, measurements, and listening sessions. It’s a bit like Lego. Sometimes you don’t immediately understand what happens in such an experimental circuit.

Fritz Fey: I’ll translate that as passion, motivation, diligence, perseverance… you just have to go where it hurts. Having an idea at four in the morning and then sticking to it… right?

Ruben Tilgner: On Saturdays, when no one was in the company, I tried things out and carried out a series of measurements. On alpha, I was already working in my parents’ basement when I was still at SPL. The crucial thing is actually to have a goal. Nine failed attempts and the tenth attempt is it. If you give up the third time, you won’t achieve anything. You have to overcome failed attempts and not get discouraged. Fortunately, analog technology was still available during my apprenticeship. Anyone who wants to get into the subject today will certainly have a harder time.

Fritz Fey: What I took away from my friendship with Gerd Jüngling over decades is that analog technology is not a sober science, but a complex ‘living’ organism…

Ruben Tilgner: That’s true. If you take a capacitor, for example, there are dozens of different types. You can measure everything, but you have to transfer component properties to the audio level first, and unexpected things often happen there. But as I said, you have to have a goal and know where you want to go as a developer. As a sound engineer, I also need a sound concept. For me, this sound philosophy only came into the game in my late 20s.

Fritz Fey: Is it always your own vision or do you also listen to the market? In my experience, users are not so goal-oriented in their wishful thinking. How do you find out what the market wants?

Ruben Tilgner: If you ask like that, the SPL Transient Designer would probably never have existed. No user would have had the idea for this product. Of course, there is always a bit of market analysis involved, but I see myself much more as an innovator. My idea for the Transient Designer came out of a listening experience. I was sitting in my little home studio and listening to the latest Michael Jackson album, which had incredibly loud transients. How do they do that? I didn’t even have a compressor to experiment with.

So I built it myself. Within two days I had developed a prototype on a plug-in board that had an attack and a sustain control. There are now lots of digital ‘replicas’ of this concept, but the SPL Transient Designer and the elysia envelope are practically the analog originals.

With the alpha compressor, I didn’t ask anyone at first either. The mpressor was already a kind of offshoot of the alpha, born out of the experience of what ‘sick’ settings some engineers turn, which I would never have thought of. In this respect, the mpressor was requested by the market, but in the end, it had functions that users would never have thought of.

Fritz Fey: There are now various plug-in emulations of your devices. Aren’t you creating competition for yourself that doesn’t have to be there?

Ruben Tilgner: It’s a different platform on which a lot of people work. But there are also many others who want to work analog or at least hybrid. The plug-in is a digital implementation of the idea of the analog original. If you take the example of the mpressor again, you can do very crazy things with this device, which the plug-in can also do. This gives the digital creation its absolute reason to exist because it is clearly different from other compressor plug-ins. But when you get into the finer details, you realize that the hardware is playing on a completely different level. But since not everyone can afford such a hardware compressor for a few thousand, it’s good to have a ‘digital replacement’, differently usable through the many possible instances.

We hand over the hardware to the software engineers with certain measuring points in the circuit so that the basic character of a device is hit very accurately. Nevertheless, differences remain, because an analog amplifier cannot be emulated so exactly in detail without completely eating up the CPU power. The control voltage in a compressor can be reproduced digitally very well, but the VCA cannot be reproduced down to the last detail, if only in terms of bandwidth. In the measurement cycle for the alpha compressor, for example, I use a 100 kHz square wave signal and look at how the edge looks on the oscilloscope. Harmonics are generated that go up to 3 or 4 MHz. The amplifiers operate in this bandwidth. That’s where analog technology makes a special difference.

Fritz Fey: Is such a plug-in also a kind of promotional tool for the analog device?

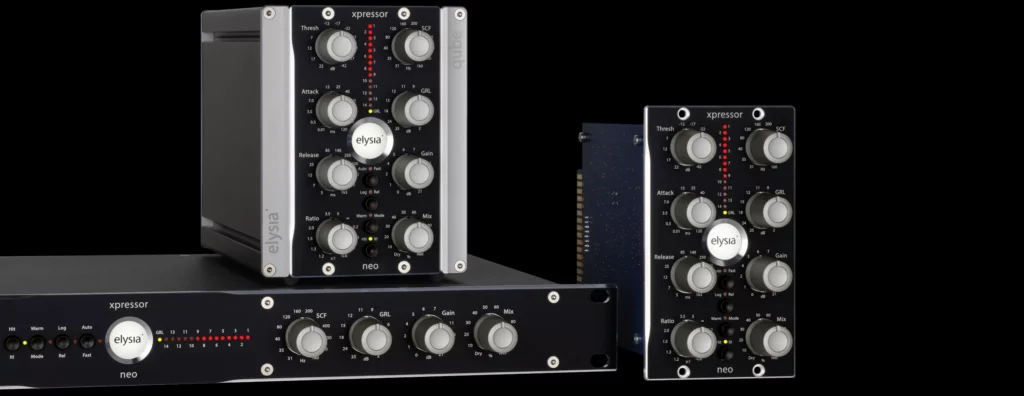

Ruben Tilgner: Definitely. I know about users who first used the plug-in and then decided to use the analog device. I honestly didn’t even suspect that it could develop in this direction. In our field with 19-inch devices and 500 modules, this is even more conceivable than with analog mixing consoles, which are light years away from the plug-in in terms of price or are even no longer being built.

Fritz Fey: The lion’s share of plug-ins are emulations of an analog original. Could this eventually lead to analog devices only being developed as templates for plug-ins?

Ruben Tilgner: Basically, from my point of view, digital technology has been reaching its limits for some years now, because the flood of software and digital hardware has not reached what good analog products can do. On the other hand, I also see a certain stagnation in the analog sector.

Here, too, analog equipment concepts are copying themselves to some extent. Many things were already developed in principle thirty or forty years ago. Of course, some of these are excellent devices, but I miss the innovation, the different concepts, and the independence. Digital technology is actually more ‘original’ in this respect. So the question is not whether analog technology retains its right to exist, but where the innovation process remains. Sound in itself isn’t all that innovative, but it is of course the domain of analog technology.

Fritz Fey: Plug-ins today represent an unbelievable variety, what feels like a hundred equalizers, compressors, reverbs, saturation, and tape machine simulators. Everything is in unmanageable quantity and for unbelievably small money. What is there to be said for analog technology with its manageable range of products, usually for a relatively large amount of money?

Ruben Tilgner: Many promises in the digital world are not fulfilled and you can buy a lot of EQ plug-ins without experiencing a real improvement in the sound. Anyone who has ever worked with a good analog EQ will know how big the leaps in quality to a new level of sound can be. The trick is to use a few analog tools as efficiently as possible because the secret is not in opening up quite a few instances or storing settings.

When I’m recording with analog gear, so I’m also making a sound decision, all I have to do in the DAW is pull up the knob and the signal is there. That’s where I really save time. As I said, it’s in the world beyond 20 kHz that things get really exciting. You can hear these differences even when comparing analog devices that are discrete and not built with integrated circuits. Analog is not better by definition. Some amplifiers make 10 volts per microsecond.

At a sampling rate of 48 kHz, we are at about 20 microseconds from one sample to the next. That’s the resolution range we’re talking about, and that’s often called the mojo or emotional level in analog. There is a difference between digitally recording a signal that has been processed in analog and processing it on the digital level. You simply have to look for coherent approaches to integrating analog technology as perfectly as possible into the modern DAW environment. A large analog mixing console is certainly not the solution, if only for economic reasons.

Fritz Fey: Not only plug-ins adorn themselves with the emulation of famous analog classics and brands, but numerous analog developments are ‘inspired’ by historical circuits.

Ruben Tilgner: That’s right. I think every manufacturer has its own ‘fingerprint’ or sound philosophy and I think it’s also legitimate to implant a proven sound character into a new device. It’s just a pity that you see proportionally very few new developments and ideas. There are so many 1176 clones or Fairchild replicas. This all sounds very nice without any question, but is this really the way forward for analog?

Some of the schematics of these classics are in the public domain and then it seems obvious to recreate something like this, maybe even improve on it. Just as the analog world copies itself to some extent, just as the digital world copies analog technology, music and sound copy each other all the time.

I miss inspiration and innovation here. The tutorial videos, perhaps even unintentionally, constantly set rules and provide recipes for how something should be. There, as well, ways of working are constantly being copied. Maybe it’s too uncomfortable or too risky to leave the paths set by professionals?

Fritz Fey: Of course, this also has to do with the “amateurization” of the industry, with people who want to get to the top quickly and then look at the people who are already there.

Ruben Tilgner: The people who are already at the top have certainly experimented a lot to get there. Those who emulate that forget that you can’t put a template over any musical performance and copy success or ‘quality’ with it. You have to reorient yourself every time, which shows how elementarily important it is what happens in front of the microphone and that you are always challenged to react to it individually.

Maybe this doesn’t sound so popular, but I think it would be cooler if the recordings were only made by people who have the skills. Because of the studio structure at the time, this was practically inevitable. In addition, the recording industry has let itself be taken out of the scepter and has thus deprived itself of an important task, namely to discover and promote talent. The market today seems to be dominated by people who can do everything, but only a bit of everything…

Fritz Fey: When I look at your product line, I see EQs, dynamics processing, saturation, and many special shapes and functions… what does ‘innovation’ mean to you in terms of analog equipment? It would have to be something that breaks through previously known boundaries…

Ruben Tilgner: It’s not the completely new processor that you come up with, it’s more the use of the devices. That’s where you have to think a bit bigger and look at how music is created or generated. I would compare it to MIDI programming a guitar that can’t do what a real guitarist plays.

The guitarist shapes his sound with effects devices directly as he plays and as a creative reaction. Through the feel and the sound, this musical-sound creativity is also created in the studio with analog devices. The best example are analog synthesizers, which became popular in the early 80s. Although there are tons of digital emulations, analog ‘new or replicas’ are extremely in demand again right now.

Once because of the sound aesthetics, which is really different, but also because of the feel. If you combine this with digital possibilities in the right way, analog technology takes on an outstanding significance again.

Fritz Fey: I would attribute the existence of numerous digital controllers to this, some of which even exactly reproduce the surface of the plug-in. Would it also be conceivable to control an analog black box with a plug-in and thus combine the advantages of both worlds?

Ruben Tilgner: Technically, this is certainly both conceivable and feasible. You have to think about how to integrate it sensibly into a production process because this combination presupposes that I want to edit an analog sound result afterward. Of course, analog technology suffers from a lack of recall. For me it’s like this: the more I use analog technology, the more final decisions have to be made at an early stage. In the days of analog tape machines, you were limited to 24 tracks and had to figure out a strategy for getting along with that.

This limitation is exactly what challenges you creatively. In the DAW, you’re easily running 80 tracks for some little ditty, with at least two or three plug-ins on each channel. When you think about the number of parameters you have to control and keep track of, it’s hard to imagine. My analog idea is to work differently, with analog processing for the recording that you commit to. Then there’s no need for recall because everything that’s recorded already sounds the way it should. Why do all sound decisions necessarily have to be postponed? Of course, you also have to develop a sound idea and a musical goal, and that’s something that’s possibly lacking today.

Fritz Fey: Do you have any new equipment concepts in mind that you can already talk about?

Ruben Tilgner: Yes, but still very vague. I’ll put it another way – there are a few things that work much better in analog than in digital. If you link analog devices, it happens without latency. If the linking is not serial, but parallel, it gets even more complicated. If you implement something like this cleverly, you can gain various advantages from it. Another aspect is that for me the analog is always the original. In the digital world, there are always only images of it – of a particular synthesizer, guitar amp, microphone, or drum kit. The development is clearly going in the direction of ‘imitation’ or ‘virtualization’.

In my opinion, the path should lead in the other direction again. Analog is not a counterpart to digital technology, but analog are also all musicians and all instruments. Of course, it takes much more effort to work with microphones and to determine the final sound with them. We have to learn again to define the quality at the beginning. In the process, I make mistakes and have to try things out…

Fritz Fey: This kind of production, which has already existed, is considered a luxury today. You need good-sounding rooms, many microphones, musicians – everything is very expensive. You can get that ‘sort of’ for $25.90 into the computer. We are sitting here in a room that has been acoustically planned and developed. Is this your private music playground or also the test station for your analog developments?

Ruben Tilgner: I have this room to understand the production process, but I also make recordings here with artists for my own projects. It’s a certain luxury that the company affords, but I just want to figure out how to get an optimal signal when recording. How do microphone preamps differ, how do microphones sound? Where can I use analog equipment efficiently? The quality is most likely to be decided at the source. It’s absurd to throw a lot of plug-ins at what is actually a bad signal to make it usable. Where did the magic come from in the earlier recordings that is so often missing today? The technology I develop is only a small part of this process, but it has to be applied at a crucial point. Our industry tries to convey to users that the tool is paramount.

Fritz Fey: You also have a control room a few doors down, which was planned and built by Dennis Busch. Do you currently have your own music project?

Ruben Tilgner: Yes, I do, but without commercial interests. I am currently working with an artist, composing and producing songs with her. But of course, I don’t have the time to make more of it.

Fritz Fey: Another topic – when you showed me the production earlier, I had the feeling that you had a certain prophetic gift because it looks as if you had already started a long time ago to make yourself more independent in terms of production. Did you foresee the current procurement problems that many companies are suffering from?

Ruben Tilgner: Of course, for me as a developer, the production process is a very exciting matter. Many years ago, I had the opportunity to look at manufacturing at Rohde & Schwarz. Back then, when elysia moved from the basement here to this building, I started thinking about this topic. It has less to do with prophetic gifts and more to do with implementing production sensibly, especially because of the small quantities we produce compared to large manufacturers.

You have to spend a lot of money to buy the appropriate machines. I had the idea of how we produce today five or six years ago. It has proven very useful to be able to control delivery times and be more independent in the area of metal processing or SMD assembly. What we practice here could be called ‘professional small series production’. Of course, there are not just people here who solder everything together by hand, which is always so aptly described as ‘manufacture’.

In another environment, our SMD pick-and-place machine would perhaps assemble 200 boards, in our case only 30, but with the same professional quality. The metal parts, which we mill completely ourselves, also give us a very high degree of independence, but we also learn about the manufacturing processes, for example how to simplify a changeover from one product to another.

Fritz Fey: In the meantime, are you experiencing what other manufacturers are also complaining about, namely poor availability of components and/or exorbitantly high prices?

Ruben Tilgner: Let’s put it this way – in electronics purchasing, there have always been problems with immediate availability when you have to buy 600 different components, as we do. For example, one and a half years ago we already had procurement problems with certain resistor types, whereupon we switched to an alternative. There are of course areas with really serious procurement problems, for example, microcontrollers, FPGAs, and AD/DAs – but since we don’t use these at all, we are not affected by them and have always been able to find solutions for our area and keep our supply capability high. Of course, prices are rising, but that doesn’t mean we have to constantly update our price lists.

Fritz Fey: As a developer of sound tools, you are at the service of music and set very high-quality standards for yourself. To what extent do you feel that this is still reflected in today’s chart music?

Ruben Tilgner: That’s a difficult topic because I can’t know which customers produce which music with my devices. I generally find the current charts problematic, since pop music is popular but not particularly sophisticated. If I look back to the 80s, the best studio musicians and producers were invited to – from today’s point of view – sinfully expensive studios to work for a Michael Jackson album, for example, which is still a reference today. Now many productions are the opposite of that: only very moderately talented singers, straightened with autotune. You don’t really hear musicians anymore, no instrument, but sound building blocks spread over an arrangement. Then begins the tedious work of somehow making that sound alive with technical means, because the sound source is not alive. If you take the analog topic a bit broader, nothing really takes place analog anymore and no finger touches an instrument. Another aspect is the loudness wave, which is by no means over.

A lot of things are still extremely driven to the wall, so I often wonder if the listener really wants that. Of course, there are still a lot of people out there who also have a high demand for quality, and of course, I hope that I make a positive contribution with my development.

Fritz Fey: I think there is a relatively high dark figure of good music (grins) that is not discovered so quickly because of the distribution structures or, in other words, is buried by garbage.

Ruben Tilgner: That’s true, but I also don’t want to be misunderstood. There is no need for every price to have people playing instruments because there are also quite great productions in the electronic field. It’s about a certain philosophy. In the 90s some albums inspired me, great recording, great spatiality, and very dynamic. That shaped in me the idea of how equipment has to sound to achieve that sound – bigger and more three-dimensional. When you flatten a production like that, as it often happens today, everything in me resists and fortunately, I’m not alone with this view…